1.SO₂ in exhaust mainly comes from raw material minerals, and SO₂ concentration is around 30-50mg/m³;

2.Leak ammonia concentration in exhaust is high, around 50-200mg/m³;

3.Water content in exhaust is relatively high, ar

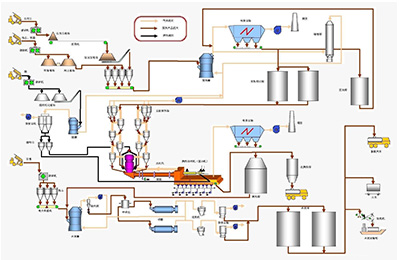

1.Usually there is no FGD in cement process, and the removal of SO₂ in flue gas is usually realized by the raw mill process, so the start and stop of the raw mill will affect the concentration of SO₂ in exhaust gas;

2.In the cement process, ammonia is injected into the Preheaters for de-NOx, which belongs to the SNCR process. Due to the low efficiency of SNCR for NOx removal, the NOx concentration in the flue gas is generally controlled by excessive ammonia injection, so the ammonia leakage concentration in the flue gas is high;

3.The moisture content in flue gas is relatively high, generally around 5% - 15%; especially when raw material is preheated and dried with raw mill puttiing into operation, the moisture content in flue gas will increase to 10% - 15%.

1.CEMS T90 response time is far more than 200s for SO₂ whole CEMS calibration, which can’t meet the requirements of 6.2.1.2 in the national standard HJ76-2017;

2.CEMS indication error is far more than ±2.5% for SO₂ whole CEMS calibration, which can’t meet the requirements of 6.2.1.3 in the national standard HJ76-2017;

3.There are condensed water and ammonia salt deposit in the pipeline of CEMS, which block the pipeline and lead to frequent maintenance of the system.

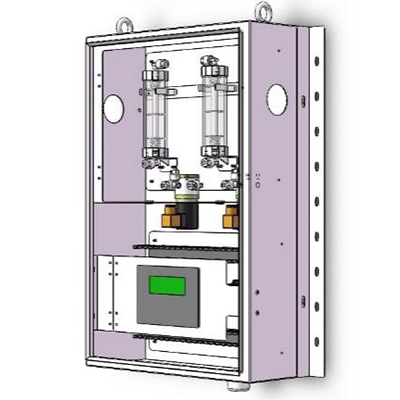

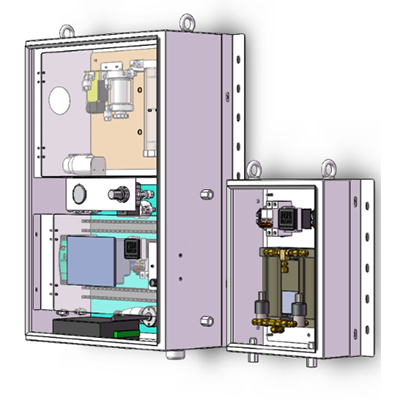

Recommend PreGASS-2400 ammonia scrubber and PreGASS-9600 precondition systems to handle ammonia salt and condensed water problems, retain target acid gases, in order to guarantee precision of monitoring system, and keep CEMS operated in a long-term, stable and reliable way, and realize the real reaction of procedure actual operation.

PreGASS-2700 ammonia scrubber system PreGASS-9600 preconditiioning system

1.AlwaysBrong provides professional on-site survey service to fully understand the actual operation and problems of on-site CEMS;

2.Evaluate based on specific conditions and problems onsite, and put forward professional tailor-made solutions;

3.Complete on-site installation and commissioning, ensure the correct implementation of the solution and achieve the corresponding performance;

4.Continuously track the operation of the system to ensure that the problems have been solved and meet the expectations of the solution.